Raw material wood

A wonderful raw material!

In clear contrast to all materials that can be used as alternatives for the production of packaging and transport materials - be it steel, plastic, paper or cardboard - wood has by far the best ecological balance. This is simply because wood is the only material that grows and binds CO2 as it grows. The wooden packaging acts as CO2 storage during its lifetime. In all the countries where sustainable forestry is practiced, only as much wood is taken from the forests as is grown back. A cycle that you could only wish for.

hapack only uses wood from sustainable forestry and is able to prove this. FSC, PEFC and carbon footprint are no foreign words. The “Carbon Calculator” software can be used to demonstrate the CO2 footprint of each pallet.

As the only treatment method to comply with international regulations (ISPM 15) and for prophylactic treatment against mold infestation, hapack deliberately only uses technical wood drying - without any chemicals. Environmentally friendly generation of the required energy by using the remaining wood from production completes the picture.

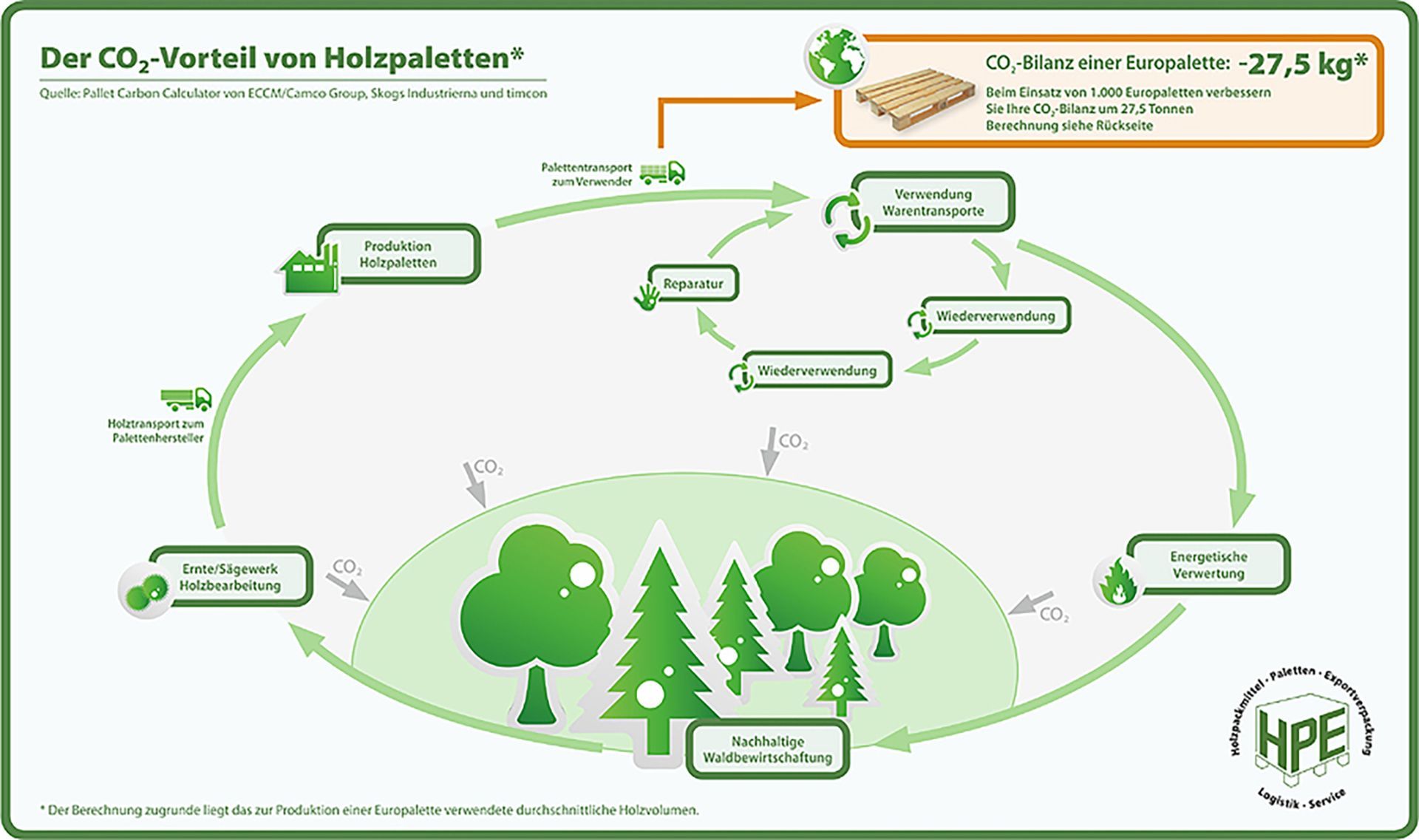

The CO2 advantage of wooden pallets as a clear diagram (Source: HPE)

The CO2 balance of a wooden pallet is extremely positive compared to a plastic pallet:

- 27.51 kg for the Euro pallet to 44.62 kg for the plastic pallet.

The main reason: the CO2 stored in the wood. This CO2 also remains stored in the wood products. The CO2 is only released again through combustion or rotting - so wood is CO2-neutral.